Power tiller is a prime mover in which the direction of travel and its control for field operation is performed by the operator walking behind it. It is also known as Hand tractor or Walking type tractor. The concept of power tiller came in the world in the year 1920. Japan is the first country to use power tiller on large scale.

In Japan, the first successful model of power tiller was designed in the year 1947. Production of power tiller rapidly increased during the year 1950 to 1965. Power tiller was first introduced in India in the year 1963. Manufacturing of several makes of power tillers like Iseki, Sato, Krishi, Kubota, Yanmar and Mitsubishi were started in India after 1962.

Power tiller is a walking type tractor. The operator walks behind the power tiller, holding the two handles of power tiller in his own hands. Power tiller may be called a single axle walking type tractor, though a riding seat is provided in certain designs.

A power tiller consists of the following main parts:

1. Main Clutch

2. Transmission gears

3. Clutch

4. Rotary unit

All the power tillers are fitted with an I.C. engine. At present, most of the power tillers are fitted with diesel engine. Only Iseki make have used kerosene engine. Other makes like Kubota, Mitsubishi, Krishi, Yanmar and Satoh have used diesel engine in India.

Operation:

The main clutch is a lever on the handle. The lever can be shifted to on or off position while operating in the field. When the lever is shifted to on position, the power from the engine is transmitted through the main clutch to the various parts of the power tiller. When the lever is shifted to off position, the power from the engine is cut-off from the rest of the transmission.

Power Transmission in Power Tiller:

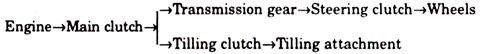

For operation of power tiller, the power is obtained from the I.C. engine, fitted on the power tiller. The engine power goes to the main clutch with the help of belt or chain. From main clutch, the power is divided in two routes, one goes to transmission gears, steering clutch and then to the wheel. The other component goes to the tilling clutch and then to the tilling attachment.

The flow diagram for transmission of power is given below:

V-belt is usually used to transmit power from the engine to the main clutch, because V-belt has very high efficiency and it works as a shock absorber also.

1. Main Clutch:

Power goes from the engine to the main clutch.

Clutch can be of following two types:

(a) Friction clutch or

(b) V-belt tension clutch

Friction clutch is generally used for bigger power tiller. Usually it is a dry type multiple disc clutch. V-belt tension clutch is used for small power tillers.

The main functions of clutch in a power tiller are:

(i) To transmit engine power to transmission gears and

(ii) To make power transmission gradual and smooth

A. Trouble – Clutch Slips:

Some of the causes and remedies are as follows:

1. Cause – Oil inside the clutch. Remedy – Clean with gasoline and dry it

2. Cause – Worn lining. Remedy – Replace the lining

3. Cause – Spring tension not sufficient. Remedy – Replace the spring

4. Cause – Water inside the clutch. Remedy – Dry it with heater etc.

5. Cause – Poor adjustment of clutch. Remedy – Adjust the clutch

6. Cause – Poor contact of friction surface. Remedy – Grind the surface

B. Trouble – The Clutch is Not Disengaged:

Some of the causes and remedies are as follows:

1. Cause – Poor adjustment of clutch. Remedy – Adjust it correctly

2. Cause – Corrosion or rust on the pressure plate. Remedy – Reface with sand paper or a file

3. Cause – Poor contact of friction surface. Remedy – Reface with sand paper or a file

2. Transmission Gears:

Transmission box consists of gears, shafts and bearings.

The Speed Change Device May Be:

(a) Gear type or

(b) Belt type

3. Brakes:

All power tillers have some braking arrangement for stopping the movement. Most of the power tillers use Inner side expansion type brake.

Wheels:

Usually 2 to 4 ply pneumatic tyres are used in power tillers. The pressure of the tyre ranges from 1.1 to 1.4 kg/cm2.

4. Rotary Unit:

Power tiller has a rotary unit for field operation.

Rotary Unit is of Two Types:

i. Centre drive type (transmission at the centre)

ii. Side drive type (transmission at one side)

i. Centre Drive Type:

It has the following characteristics:

(а) Tilling width can be widened

(b) Rotary unit is light in weight

(c) Fixing of attachment is easy

(d) The tine shaft can be detached easily

(e) Mounting and dismounting of rotary unit is very easy

(f) It may leave some portion of the field unfilled

(g) It has one point support on the ground.

ii. Side Drive Type:

Characteristics of Side Drive Type:

(a) Deeper tilling is possible

(b) The arrangement is useful for hard soil

(c) It has two points support on the ground

Rotary Tines:

Rotary tines are used in rotary unit for soil cutting and pulverisation purpose.

Rotary Tines are of Three Types:

i. Straight Tines:

In Case of Straight Tines:

(a) Power consumption is less

(b) Fine pulverization of soil is possible

(c) Poor soil turning

(d) Grass entangles in the tines very easily

(e) It is suitable for hard soil

ii. Curved Tines:

In Case of Curved Tines:

(a) Good soil turning is possible

(b) It is suitable for avoiding grasses

(c) Pulverization of soil is coarse and

(d) Power consumption is high

iii. Sliding Tines:

Sliding tines have the characteristics of sliding on their positions according to the requirement.

The tines can be arranged in three ways:

a. Inner heap (to break the ridges)

b. Outer heap (to make the ridges), and

c. Even arrangement

Steering Clutch Lever:

Steering clutch is provided on the grip of the right and left handles. When the left side is gripped, power is cut-off on left side of the wheel and the power tiller turns to the left. Similarly when the right side is gripped, the power tiller turns to the right.