A tractor is made of following main units: 1. Clutch 2. Transmission Gears and Torque Converter Gear 3. Differential Unit and Final Drive 4. Steering System and Brake Steering System 5. Hydraulic Control System 6. Hitch and Control Board of Tractor 7. Power Take-Off Unit (Pto) 8. Belt Pulley 9. Control Board or Dash Board of a Tractor 10. Tractor Tyre and Front Axle.

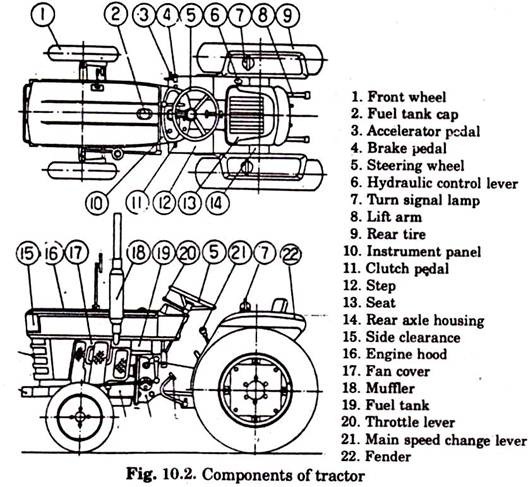

Fig. 10.2 shows the important components of the tractor. Every tractor is fitted with an I.C. engine. Now a days almost all the tractors are diesel tractors.

Component # 1. Clutch:

Clutch is a device, used to connect and disconnect the tractor engine from the transmission gears and drive wheels. Clutch transmits power by means of friction between driving members and driven members.

Necessity of Clutch in a Tractor:

Clutch in a tractor is essential for the following reasons:

1. Engine needs cranking by any suitable device. For easy cranking, the engine is disconnected from the rest of the transmission unit by a suitable clutch. After starting the engine, the clutch is engaged to transmit power from the engine to the gear box.

2. In order to change the gears, the gear box must be kept free from the engine power, otherwise the gear teeth will be damaged and engagement of gear will not be perfect. This work is done by a clutch.

3. When the belt pulley of the tractor works in the field it needs to be stopped without stopping the engine. This is done by a clutch.

Essential Features of a Good Clutch:

1. It should have good ability of taking load without dragging and chattering.

2. It should have higher capacity to transmit maximum power without slipping.

3. Friction surface should be highly resistant to heat effect.

4. The control by hand lever or pedal lever should be easy.

Types of Clutch:

Clutches are mainly of three types:

1. Friction clutch

2. Dog clutch

3. Fluid coupling

Friction clutch is most popular in four wheel tractors. Fluid clutch is also used in some tractors these days. Dog clutch is mostly used in power tillers.

1. Friction Clutch:

Friction clutch produces gripping action, by utilizing the frictional force between two surfaces. These surfaces are pressed together to transmit power.

While starting the engine, the clutch pedal is depressed. After the start of the engine, the clutch pedal is slowly released to increase the pressure gradually on frictional surfaces until there is no slip. Thus the driven plate is gripped firmly to the driving plate. Transmission of power depends upon the kind of material used for the friction members and intensity of the force, pressing them together.

Friction clutch may be subdivided into three classes:

(i) Single plate clutch or single disc clutch

(ii) Multiple plate clutch or multiple disc clutch and

(iii) Cone clutch.

(i) Single Plate Clutch:

This may be called- Single disc clutch.

It consists of:

a. Pressure plate

b. Clutch plate

c. Springs and

d. Release fingers.

There is only one clutch plate in this type. The clutch plate is pressed against the flywheel of the engine by means of spring loaded pressure plate. When the pedal of the clutch is depressed, the pressure plate is pushed back by the release fingers. This releases the pressure from the clutch plate.

Then the clutch plate stops rotating but the flywheel continues to rotate. When the clutch pedal is released, the pressure plate forces the clutch plate against flywheel to cause the clutch plate and the flywheel to turn together as one unit. Thus the power of the engine goes to the gear box for onward transmission to rear wheels.

(ii) Multiple Plate Clutch:

This may be called multiple disc clutches. It has got a number of thin metal plates, arranged alternately to work as driving and driven members. One set is attached to the flywheel and the other set is attached to the clutch shaft. If the plates are pressed together, the clutch is said to be engaged and the power is transmitted from the engine to the gear box for onward transmission to the rear wheels. This pressure is obtained by a set of heavy springs, fitted together in housing.

Engagement and disengagement of this type of clutch is very smooth due to larger surface area of friction members.

2. Dog Clutch:

It is a simple clutch having square jaws which are used to drive a shaft in either direction. It is mostly used in power tillers.

3. Fluid Coupling:

Fluid coupling consists of a driving member and a driven member. An impeller with radial vanes constitutes the driving member and runner with radial vanes constitutes the driven member. The entire unit is housed in a suitable casing. A coupler is mounted on the engine crankshaft and is 3/4th filled with suitable oil.

A spring loaded sealing ring is provided to make the driven shaft oil tight. At the rotation of the crankshaft, the oil is thrown out by centrifugal force from the centre to the outer edge of the impeller, increasing the velocity and the energy of the oil.

It then enters the runner vanes at the outer portion and flows towards the centre, causing rotation to the runner unit. As long as impeller and runner rotate at different speeds, the oil continues to circulate uniformly but when the impeller and runner start running at same speed, the circulation of oil stops. The coupling does not increase the applied torque but only transmits the torque in a uniform manner.

The main features of fluid coupling are:

i. Absorption of shock and vibration.

ii. Smooth starting and

iii. Easy operation

Component # 2. Transmission Gears and Torque Converter Gear:

A tractor engine runs at high speed, but the rear wheel of the tractor requires power at low speed and high torque. That’s why it becomes essential to reduce the engine speed and increase the torque available at the rear wheels of the tractor because-

T is torque in newton-metre (N.m)

n = speed in rev/min

If the engine power is constant, it is obvious that for higher torque at wheels, low speed is required and vice versa. So the gear box is fitted between engine and rear wheel for variable torque and speed. This is done by suitable design of gear and shafts.

Speed varies according to the field requirements and so a number of gear ratios are provided to suit the varying conditions. Gears are usually made of alloy steel. As the tractor has to transmit heavy torque all the time, best quality lubricants free from sediments, grit, alkali and moisture, is used for lubrication purpose.

Common gears used on tractors are of two types:

1. Selective sliding type

2. Constant mesh type

1. Selective Sliding Type:

The gear box consists of:

(i) Gear housing,

(ii) Gear shifting lever,

(iii) Main shaft or input shaft,

(iv) Output shaft and,

(v) Lay shaft or countershaft

A number of gears are mounted on these shafts .The main shaft is directly connected to the clutch and carries gears. The gears are liable to slide. The gears are shifted with the help of shifting lever and shifting fork.

The gears are shifted along the shaft, to which they are splined to engage with another gear as and when desired to connect the power train. The gears are of different diameters having different number of teeth. Speed is reduced in proportion to the number of teeth provided on the gears.

2. Constant Mesh Type:

These gears are always in mesh. Usually the gears are helical in shape. The transmission is put into operation by engagement of shifting couplings which slide along the splines on the counter shaft and the output shaft of the gear box.

Torque Converter:

This is also called hydro-kinetic transmission. It is a device used on tractors for transmission of power and for multiplying the torque of the engine.

It works as a torque multiplier.

Torque converter consists of:

i. Impeller

ii. Turbine

iii. Stator and

iv. Housing

In this system, the engine flywheel is connected to an impeller which has got blades and is contained in a housing having suitable oil. As the flywheel rotates, it turns the impeller, which strikes against the oil in the container (Fig. 10.9). The driven oil strikes the blades of the turbine, forcing it to spin, creating high input torque. The swirling oil rebounds off the turbine blades against the stator. The flow of oil against the stator creates a back force.

This is a reaction torque and it is added to the input torque. The swirling oil bounces off the stator and is redirected back into the spinning impeller blade. Thus the circulating oil is driven around and around, bouncing from impeller to turbine, to stator to impeller, helping itself to multiply the torque.

The turbine is connected to the output shaft of the torque converter. Its twisting power (torque) is geared to the rear wheels of the tractor. The torque converter takes low torque at high speeds and converts it to high torque at low speeds.

Component # 3. Differential Unit and Final Drive:

Differential Unit:

Differential unit is a special arrangement of gears to permit one of the rear wheels of the tractor to rotate slower or faster than the other. While turning the tractor on a curved path, the inner wheel has to travel lesser distance than the outer wheel.

The inner wheel requires lesser power than the outer wheel; this condition is fulfilled by Differential unit, which permits one of the rear wheels of the tractor to move faster than the other at the turning point. The output shaft coming from the gear box is provided with a bevel pinion at the end of the shaft. The bevel pinion is in mesh with a large bevel wheel known as Crown wheel.

The Main Functions of Crown Wheel Assembly are:

1. To transmit power through right angle drive to suit the tractor wheels.

2. To reduce the speed of rotation.

The differential unit consists of:

1. Differential casing

2. Differential pinion

3. Crown wheel

4. Half shaft and

5. Bevel gear

The differential casing is rigidly attached with the crown wheel and moves like one unit. Two pinions are provided inside the differential casing, such that they are carried round by the crown wheel but they are free to rotate also on their own shaft or stud. There are two or more bevel gears in mesh with differential pinion.

One bevel pinion is at the end of each half shaft, which goes to the tractor rear wheel. Thus instead of crown wheel being keyed directly to a solid shaft between the tractor wheels, the drive is taken back from the indirect route through differential casing, differential pinion and half shaft of the tractor. When the tractor is moving in a straight line, the differential pinion do not rotate on the stub shaft but are solid with the differential casing. They drive the two bevel gears at the same speed and in the same direction as the casing and the crown wheel. [Fig. 10.11 and 10.12]

Fig. 10.11 shows that when vehicle is going straight, sun and star pinion do not revolve on their axis but run as one unit.

Fig. 10.12 shows that when vehicle turn, star and sun pinion move on their own axes apart from moving by pinion carrier.

Each differential pinion can move in two planes simultaneously. When it is carried round by the casing, it drives the half-shaft in the same direction but when it is rotated on its own shaft, it drives them in opposite direction i.e. rotation of differential pinion adds motion to one shaft and subtracts motion from the other shaft.

Differential Lock:

Differential lock is a device to join both half axles of the tractor so that even if one wheel is under less resistance, the tractor comes out from the mud etc. as both wheels move with the same speed and apply equal traction.

Final Drive:

Final drive is a gear reduction unit in the power trains between the Differential and the Drive wheels. Final drive transmits the power finally to the rear axle and the wheels. The tractor rear wheels are not directly attached to the half shafts but the drive is taken through a pair of spur gears. Each half shaft terminates in a small gear which meshes with a large gear called Bull gear. The Bull gear is mounted on the shaft, carrying the tractor rear wheel. The device for final speed reduction, suitable for tractor rear wheels is known as Final drive mechanism.

Component # 4. Steering System and Brake Steering System:

The system, governing the angular movement of front wheels of a tractor is called Steering system. This system minimizes the efforts of the operator in turning the front wheel with the application of leverages.

The different components of the system are – (i) Steering wheel, (ii) Steering shaft, (iii) Steering gear, (iv) Pitman arm (drop arm), (v) Drag link, (vi) Steering arm, (vii) Tie rod and (viii) King pin.

When the operator turns the steering wheel, the motion is transmitted through the steering shaft to the angular motion of the pitman arm, through a set of gears. The angular movement of the pitman arm is further transmitted to the steering arm through the drag link and tie rods. Steering arms are keyed to the respective kingpins which are integral part of the stub axle on which wheels are mounted. The movement of the steering arm affects the angular movement of the front wheel.

In another design, instead of one pitman arm and drag link, two pitman arms and drag links are used and the use of tie rod is avoided to connect both steering arms.

Brake:

Brake is used to stop or slow down the motion of a tractor. It is mounted on the driving axle and operated by two independent pedals. Each pedal can be operated independently to assist the turning of tractor during the field work or locked together by means of a lock.

Principle of Operation:

Brake works on the principle of friction. When a moving element is brought into contact with a stationary element, the motion of the moving element is affected. This is due to frictional force which acts in opposite direction of the motion and converts the kinetic energy into heat energy.

Classification of Brake:

Brake can be classified as:

1. Mechanical brake and

2. Hydraulic brake

1. Mechanical Brake:

Mechanical brake can be of two types:

(a) Internal expanding shoe type

(b) External contracting shoe type and

(c) Disc type

(a) Internal Expanding Shoe Type:

Two brake shoes made of frictional material fitted on the inside of the brake drum are held away from the drum by means of springs. One end of each shoe is fulcrumed whereas the other is free to move by the action of a cam which in turn applies force on the shoes. The movement of the cam is caused by the brake pedal through the linkage. The drum is mounted on the rear axle whereas the shoe assembly is stationary and mounted on the back plate.

(b) External Contracting Shoe Type:

This type of brake system is normally available on crawler tractors. The drum mounted on the drive axle is directly surrounded by the brake band. When the pedal is depressed, the band tightens the drum.

(c) Disc Brake:

Two actuating discs have holes drilled in each disc in which steel balls are placed. When the brake pedal is depressed, the-links help to move the two discs in opposite directions. This brings the steel balls to shallow part of the holes drilled in the disc.

As a result, the two discs are expanded and braking discs are pressed in between the discs and the stationary housing. The braking discs are directly mounted on the differential shaft which ultimately transfers the travelling effect to the differential shaft.

2. Hydraulic Brake:

Hydraulic brake system is based on the principle of Pascal’s law. The brake fluid which is usually a mixture of glycerin and alcohol is filled in the master cylinder. When the pedal is depressed, the piston of the master cylinder is forced into the cylinder and the entire system turns to a pressure system.

Immediately, the piston of the wheel cylinder slides outward which moves the brake shoes to stop the rotating drum. When the pedal is released, the return spring of the master cylinder moves the piston back to its original position, causing a sudden pressure drop in the line. The retracting springs of the brake shoe bring them back to their original position. Thus the piston of the wheel cylinder returns back.

Component # 5. Hydraulic Control System:

It is a mechanism in a tractor to raise, hold or lower the mounted or semi-mounted equipments by hydraulic means. All tractors are equipped with hydraulic control system for operating three point hitch of the tractor.

Working Principle:

The working principle of hydraulic system is based on Pascal’s law. This law states that the pressure applied to an enclosed fluid is transmitted equally in all directions. Small force acting on small area can produce higher force on a surface of larger area.

wt on small cylinder (W1)/area of small cylinder (A1) = wt on bigger cylinder (W2)/area of bigger cylinder (A2)

W2 is higher in the same proportion as the ratio of the areas of the two sections. A simple hydraulic system consists of a pump which pumps oil to a hydraulic ram. This pump may be driven from tractor’s transmission system or it may be mounted on its engine. This system consists of a cylinder with a close fitting piston like an engine cylinder. As the oil is pumped into the closed end of the cylinder, the piston is forced along-with it. The movement of the piston is transmitted to the lower links by means of a cross shaft and lift rods.

A control valve controls the flow of oil and directs it back to the reservoir. It allows the oil in the cylinder to flow out again when the links are to be lowered. It also traps the oil in the cylinder when the links are to be held at any height.

Precautions for Hydraulic System:

a. Correct grade of oil should be used.

b. The hydraulic oil tank should have oil up to the mark.

c. All the bolts, nuts and piping should be tightened well.

d. Filter should be checked at regular interval.

Component # 6. Hitch and Control Board of Tractor:

Hitch:

Implements are needed to be hitched properly for efficient and safe operation of the tractor.

Implements can be:

1. Trailed

2. Semi-mounted and

3. Mounted

Implements can be hitched in two ways:

1. Drawbar hitch and

2. Three point linkage

1. Drawbar Hitch:

Drawbar is a device by which the pulling power of the tractor is transmitted to the trailing implement. It consists of a crossbar with suitable holes, attached to the lower hitch links. It is fitted at the rear part of the tractor.

2. Three Point Linkage:

It is a combination of three links, one is upper link and two are lower links the links articulated to the tractor and the implements at their ends in order to connect the implement to the tractor.

Advantage of Three Point Linkage:

i. Easy control of working implements

ii. Quick setting of implements

iii. Automatic hydraulic control of implements such as position control, draft controls etc.

iv. Good balancing of attached implements.

Implement Control:

The tractor with a built in lift system is connected to the implement through a specific type of mechanical linkage termed as Three point linkage and the system is known as Mounted system. The implement is connected to the tractor hydraulic system at two bottom links and one top link. Both the bottom links are connected to two lift arms through lift links.

The lift arms are directly mounted on a rock shaft which is further connected to the piston rod. Any movement of the piston is transferred to the bottom links. The top link is used for connecting the third hitch point of the implement and is adjustable for maintaining the implement level and suction angle. Load sensing for the draft control can also be done through the top link which is spring loaded. In some tractors the lower links are spring loaded for draft sensing.

Depending upon the soil condition and type of operation the mounted implement can be controlled either by Position control or Draft control.

Weight Transfer:

Rear part of the tractor is heavier than the front part to get higher tractive efficiency. However, sufficient weight on the front axle is also required to facilitate easy steering and to compensate the effect due to weight transfer. When the load is pulled, the tendency of front axle is to become light by losing some weight and the same adds to the rear axle.

The higher the pull, the greater is the weight transfer. Mathematically this can be represented by-

Where, the line of pull is always assumed to be parallel to the ground.

Component # 7. Power Take-Off Unit (Pto):

It is a part of tractor transmission system. It consists of a shaft, a shield and a cover. The shaft is externally splined to transmit torsional power to another machine. A rigid guard fitted on a tractor covers the power take-off shaft as a safety device.

This guard is called power take-off shield. Agricultural machines are coupled with this shaft at the rear part of the tractor. As per ASAE standard pto speed is 540 ± 10 rpm when operating under load. In order to operate 1000 rpm pto drive machine, a new standard has been developed.

Component # 8. Belt Pulley:

All tractors are provided with a belt pulley. The function of the pulley is to transmit power from the tractor to stationary machinery by means of a belt. It is used to operate thresher, centrifugal pumps, silage cutter and several other machines.

The pulley is located either on the left, right or rear side of the tractor. The pulley drive is engaged or disengaged from the engine by means of a clutch. The pulley is generally made of cast iron or cast steel.

Component # 9. Control Board or Dash Board of a Tractor:

The control board of a tractor generally consists of:

1. Main Switch:

When the main switch is on, the electric current flows in the electrical circuit.

2. Throttle Lever:

This lever is for increasing or decreasing the speed of the engine.

3. Decompression Lever:

This lever releases compression pressure from the combustion chamber of the engine and helps to start the engine.

4. Hour Meter:

This meter indicates the engine hour as well as engine revolution per minute.

5. Light Switch:

Light switch is for light points only.

6. Horn Hutton:

This is for horn of the tractor.

7. Battery Charging Indicator:

This indicates the charge and discharge of the battery.

8. Oil Pressure Indicator:

This indicates the lubricating oil pressure in the system.

9. Water Temperature Gauge:

This indicates the temperature of water of the cooling system.

Component # 10. Tractor Tyre and Front Axle:

Tyre:

The tyres are available in many sizes with the ply ratings as 4, 6 or 8. The ply rating of tyres indicates the comparative strength of tyres. The higher the rating, the stronger are the tyres. The inflation pressure in the rear wheels of the tractor varies between 0.8 to 1.5 kg/cm2. The inflation pressure of the front wheel varies from 1.5 to 2.5 kg/cm2. Useful life of the pneumatic tyres under normal operating condition may be about 6000 working hours for drawbar work.

Front Axle:

Front axle is the unit on which front wheel is mounted. This wheel is an idler wheel by which tractor is steered in various directions. The axle is a rigid tubular or I-section steel construction pivoted at the centre.

Following are the various adjustments of front wheel:

1. Toe-in

2. Caster angle and

3. Camber angle

1. Toe-in:

It is the difference in the distance of the centre lines of the back end and front end of front wheels of tractor.

Adjustment of Toe-in of Front Wheels:

The spacing at the front of the wheels is slightly lesser than that at the rear of these wheels. The difference between these two measurements is called Toe-in.

If the steering wheel vibrates excessively or if it tends to catch while the tractor is in motion, check the toe-in of the front wheels.

If the toe-in is less or more than the specified limits, it should be adjusted as follows:

i. Loosen the lock nut provided at the tie rod end.

ii. Use toe-in gauge to ascertain the toe-in value in mm and adjust the turn buckle to get the desired limit.

iii. Now secure the turn buckle by tightening the lock nut.

2. Caster Angle:

It is the angle between the centre line of the king pin of the tractor and the vertical line.

3. Camber Angle:

It is the angle between the centre line of the tyre and the vertical line.