The following points highlight the top three methods used for stabilization of river banks. The methods are: 1. Self-Adjusting Armour of Stone or Other Material 2. Rigid Armour 3. Flexible Mattress.

Method # 1. Self-Adjusting Armour of Stone or Other Material:

Stone armour can be placed in four general configurations, the most common being a “riprap blanket”. Other forms, known as “trenchfill”, “longitudinal stone toe,” and “windrow” (referred to in some regions as “falling apron”), can be very useful in certain situations.

A stone armor usually consists of “graded” stone, which is a mixture of a wide range of stone sizes; the largest sizes resist hydraulic forces, and the smaller sizes add interlocking support and prevent loss of bank material through gaps between larger stones. Hand-placed stone in a smaller range of sizes is occasionally used.

The various types of stone armours are:

i. Riprap Blanket:

Riprap (Fig. 4.50) should be blocky in shape rather than elongated, as more nearly cubical stones “nest” together best and are more resistant to movement. The stone should have sharp, clean edges at the intersections of relatively flat faces. Cobbles with rounded edges are less resistant to movement, although the drag force on a rounded stone is less than on sharp-edged cubical stones.

As graded cobble interlock is less than that of equal-sized angular stones, the cobble mass is more likely to be eroded by channel flow. If used, the cobbles should be placed on flatter side slopes than angular stone and should be about 25 percent larger in diameter.

The bed material and local scour characteristics determine the design of toe protection, which is essential for riprap revetment stability. The bank material and ground water conditions affect the need for filters between the riprap and underlying material. Construction quality control of both stone production and riprap placement is essential for successful bank protection.

Riprap protection for flood-control channels and appurtenant structures should be designed so that any flood that could reasonably be expected to occur during the service life of the channel or structure would not cause damage exceeding nominal maintenance. While the procedures presented herein yield definite stone sizes, results should be used for guidance purposes and revised if appropriate, based on experience with specific project conditions.

ii. Trenchfill:

A trenchfill revetment, shown in Fig. 4.51, is simply a standard stone armor revetment with a massive stone toe. It is normally constructed in an excavated trench behind the river bank, in anticipation that the river will complete the work by eroding to the revetment, causing the stone toe to launch down and armor the subsequent bank slope.

Material other than stone, such as broken soil-cement, has been used successfully and may be less costly than stone, but careful design of the soil/cement mixture, and careful monitoring of the material mixing, breaking, and placing operation is required.

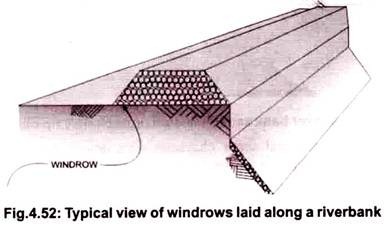

iii. Windrow:

A windrow revetment (Fig. 4.52) is simply an extreme variation of a trenchfill revetment. A window revetment consists of rock placed on the floodplain surface landward from the existing bankline at a pre-determined location, beyond which additional erosion is to be prevented.

iv. Longitudinal Stone Toe:

Longitudinal stone toe (Fig. 4.53) is another form of a window revetment, with the stone placed along the existing streambed rather than on top bank. The longitudinal stone toe is placed with the crown well below top bank, and either against the eroding bankline or a distance riverward of the high bank. Typical crown elevations may vary but are commonly between 1/3 and 2/3 of the height to top bank.

The success of longitudinal stone toe protection is based on the premise that as the toe of the bank is stabilized, upper bank failure will continue until a stable slope is attained and the bank is stabilized. This stability is usually assisted by the establishment of vegetation along the bank.

v. Concrete Blocks:

These are armour revetment for bank stabilization consisting of loose concrete blocks. Concrete blocks fastened together forms a kind of flexible mattress.

A wide variety of block shapes and placement techniques can be used. Some have evolved from engineering analyses, some from observation and empiricism, and some from improvisation using readily available materials. Blocks designed specifically for bank armor are commercially available. Forms for casting concrete blocks locally are often available from distributors, and may be an economical alternative to purchasing and transporting precast blocks.

A fabric or granular underlayment (“filter”) is often required for riverbank protection by concrete blocks. Successful performance of the underlayment is more critical than with a riprap armour. In areas of high turbulence or waves, displacement of one block can lead to successive displacement of adjacent blocks. If blocks are cast on- site, delays from inclement weather may be a problem. At sites that are subject to theft or vandalism, blocks of an attractive size and shape may suffer serious attrition.

vi. Sacks:

Sacks as an armor material can be considered to be artificial “rocks” of uniform size and shape. The sacks may be made of paper, burlap, or a synthetic material. The fill material may be soil or aggregate of various types, with or without cement. Sacks can be placed on a steeper slope than stone. Materials are often available locally. The hydraulic roughness is low, and they form a walk-able surface. The “cobblestone” effect may be more aesthetic than some other materials. As far concrete blocks, a fabric or granular filter is usually required.

vii. Soil-Cement Blocks:

Soil is mixed well with sufficient cement to provide a durable bond between soil particles. The resulting monolith is broken into blocks of various sizes, which are used to armor the bank. Besides the general characteristics of adjustability to bank irregularities and self-healing properties, soil-cement blocks allow the utilization of locally available materials. However, soil-cement blocks have a lower specific weight than riprap, and obtaining acceptable gradation and durability are highly dependent on closely controlled construction operations. Construction operations are adversely affected by wet or cold weather.

Method # 2. Rigid Armour:

Rigid armour is an erosion-resistant material which has little or no flexibility to conform to bank irregularities occurring after construction. Typically, the armour is placed directly on the bank slope in a fluid or chemically reactive state, then hardens.

The most common rigid armours are:

i. Asphalt,

ii. Concrete,

iii. Grouted Riprap (or other grouted armour material), and

iv. Soil-Cement.

The main advantages for a rigid armour are:

The most common rigid armours will withstand high velocities, have low hydraulic roughness, and prevent infiltration of water into the channel bank. They are practically immune to vandalism, damage from debris, corrosion, and many other destructive agents. The most common rigid armours are easily traversed by pedestrians.

However, a rigid armour requires careful design and quality control during construction, and unfavourable weather conditions can cause construction delays. Provision for draining groundwater and preventing the built-up of excess positive pore water pressures, in the form of a filter or subsurface drains, must usually be provided for impermeable armours, which may significantly increase the cost of the project.

Most rigid armours are difficult or impossible to construct underwater, although this difficulty can be alleviated for concrete by using one of the commercially available fabric mattresses. Asphalt has been placed underwater in some mattresses. Rigid armour, being inflexible, is susceptible to breaching if the bank material subsides or heaves. Increased wave run-up on a smooth rigid armour may be a concern for some projects.

Typical applications of rigid armour in the form of concrete, asphalt, or grouted riprap is often considered for use in situations where high velocities or extreme turbulence make adjustable armour ineffective or very expensive. Typical uses are in conjunction with hydraulic structures or in artificial channels on steep slopes. Rigid armour may be the preferred alternative in flood control or drainage channels where low boundary roughness is mandatory, or in water supply channels where prevention of water loss due to infiltration into the bank is important.

It is suitable for bank slopes which must be easily traversed by pedestrians or recreational users, if the slope is not too steep for safety. Rigid armour is sometimes the least costly alternative, typically where adjustable armour is not available locally, especially if a geotechnical analysis of the bank material indicates that elaborate subsurface drainage work is not necessary.

The important types of rigid armour are:

a. Asphalt:

Asphalt mixes with a high sand content are sometimes used to retain some permeability to relieve hydrostatic pressure. However, these mixes have been reported to become more brittle and less permeable upon long exposure to the elements, and weathering may result in a slow loss of thickness.

b. Concrete:

On slopes above water, concrete can be placed in the conventional manner with forms, or can be pumped into fabric mattresses which serve as forms for a fine aggregate concrete. Prefabricated slabs would assume some of the characteristics of concrete block armour.

c. Grouted Armour:

Grouting of an armour layer with asphalt or concrete enables the armour to withstand higher flow velocities, provides a smooth surface for pedestrian or vehicle access, and reduces the hydraulic roughness of the armour. Grouting is also sometimes used with gabion armours or structures to increase the resistance of the gabions to corrosion and abrasion.

d. Soil-Cement:

Soil-cement will withstand relatively high velocities and is usually less expensive than concrete, asphalt, and grouted riprap. It is more durable than chemical stabilization, clay, and certainly ice, but usually somewhat less durable than concrete, asphalt, and grouted riprap, assuming that sound design and construction procedures are followed for all.

Method # 3. Flexible Mattress:

The basic concept of a flexible mattress is that material or objects which cannot resist erosive forces separately can be fastened together or placed in a flexible container to provide adequate resistance to erosive forces, while partially retaining the desirable characteristics of adjustable armour, especially that of flexibility.

The most common flexible mattress materials are:

i. Concrete Blocks;

ii. Fabric; and

iii. Gabions.

The advantages of this type of riverbank protection work includes its flexibility to adjust to scour or settlement and still remain in contact with the bed and bank is the most obvious shared trait. Most mattress materials which are sold under trade names share another advantage they are available in various configurations, thus can be applied to a variety of situations. Flexible mattresses can be placed underwater with a relatively high degree of confidence. If properly anchored to a geotechnically stable bank, they can be placed on steep slopes. They can be walked upon easily, thus are suitable for slopes used by pedestrians.

However, it must be kept in mind that mattress components are subject to deterioration from the elements and vandalism. The damage is often within acceptable limits through, and, since the various types are affected differently, identification of the hazards enables the designer to select an appropriate mattress for a given application. The construction of some types of mattress is labour intensive, and may require skills not commonly available. However, the labour intensive aspect may not be a disadvantage in all cases, and may be an advantage in some cases.

Typical applications of flexible mattresses are:

This compromise between adjustable armour and rigid armour is most attractive when economical materials can be used for the mattress. In fact, the origin of some variations can be traced directly to creative use of local materials where no protective material of local origin was adequate to withstand the erosive forces in a given application, and where the most suitable method was the one which required the least amount of costly imported material, a requirement which is often met by a flexible mattress.

Some of the common forms of flexible mattresses are:

i. Concrete Block Mattress:

Mattresses provide a higher degree of safety from progressive failure of the armour due to displacement of individual blocks from hydraulic or geotechnical forces or vandalism. Placing of mattresses is more mechanized and less labour intensive than placing individual blocks. Precast concrete blocks can be formed into a flexible mattress in several ways- By fastening them to engineering fabric, by fastening them together with cable or synthetic rope, or by forming them in ingenious shapes which are then interlocked. All of these varieties are commercially available.

ii. Fabric Mattress:

Fabric mattresses made of synthetic material and filled with concrete grout, other cohesive mixtures, or sand are available from various manufactures. Tubular-shaped bags are also available; these can be filled and placed either parallel to the streambank as a bulkhead or perpendicular to the streambank as a dike, or can be used to fill scour holes or undermined slopes. A fabric mattress is relatively easy to place, and fill material is often available locally. Some designs have a low hydraulic roughness.

iii. Gabion Mattress:

A gabion mattress consists of a mesh container filled with cobbles or quarried stone. Several firms market the containers and furnish technical assistance. Spacialized equipment or accessories used on large jobs for efficiency, or on jobs requiring underwater placement.

A form of gabion which is a hybrid between flexible mattress and adjustable armour is the “sack” or “sausage,” which can be filled faster than mattress or box shapes, making it suitable for use in emergency situations. However, it makes less efficient use of material, and is less common than traditional mattress or boxes.

iv. Vegetation (Fascine) Mattress:

Wooden mattress is one of the oldest techniques of bank stabilization, even though it is seldom used now in developed regions. The mats may be made of poles, brush, or lumber. The material can be fastened together by weaving, binding, cabling, clamping, or spiking. The mattresses are sunk by ballasting with stone or other heavy materials. Some types of mat may be so buoyant that the ballast is a significant component of the protection, as well as a large part of the cost.

On navigable rivers during periods when current speed is slow enough that the mats can be safely maneuvered in tow, mats with sufficient buoyancy can be safely maneuvered in tow, mats with sufficient buoyancy can be assembled near the materials supply point or near a source of labour, then towed to the project site.

At least one marine construction firm has adapted modern technology to the construction of wooden mattress, while still retaining traditional skills for use where appropriate. They have also extended new technology to the point of developing synthetic materials for use in mattresses, in order to overcome some of the inherent problems of wood.

The main advantage of this type of bank protection is that its main raw material, that is, wood is usually available locally, and is a renewable resource. If inexpensive labour is available, a wooden mattress may be the least cost alternative. Wood is relatively durable when permanently submerged in freshwater. However, near-site availability of material is usually required for wooden mat to be competitive with other methods.