In this article we will discuss about the manufacture of dried milk by drum and spray process.

Method of Manufacture by Drum Process of Whole Milk Powder (WMP) and Skim Milk Powder (SMP):

Flow diagram = Combined for WMP and SMP:

Details:

1. Whole Milk Powder:

(a) Receiving Milk:

Only high-grade milk should be accepted.

(b) Filtration/Clarification:

The chief object of this is to remove extraneous matter.

(c) Standardization:

This is done to adjust the ratio of fat and solids-not-fat in raw milk to meet the legal standards for composition in dried whole milk. Raw milk is standardized by adding to it a calculated amount of skim milk or cream.

Problem:

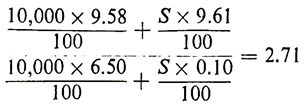

Given 10,000 kg. milk testing 6.50% fat and 9.58% SNF and skim milk testing 0.10% fat and 9.61% SNF. How much skim milk must be used for standardization so as to give whole milk powder of standard composition?

Solution:

Assuming whole milk powder to contain:

26.2% fat and 2.8% moisture.

Let the quantity of skim milk required be S kg.

Then the following equation can be framed:

Solving, S = 8,603.7 kg. Ans.

Note:

The above standardized milk will test 3.54% fat and 9.60% SNF.

(d) Forewarning:

This is important for the destruction of microorganisms and inactivation of enzymes, and for improving the physical quality of the finished product. Heating skim milk to 85°C for 10 minutes ensures good baking properties in the skim milk powder.

(e) Condensing:

Normally a total solids of 16 to 18 per cent in the condensed product is sought.

(f) Homogenization:

The whole milk is usually homogenized after concentration and before drying to reduce the proportion of free fat in the dried product, thereby lowering the chances of oxidized flavour development. The homogenization is carried out at 63-77°C (145-170°F) in two stages, 2500 psi on the first stage and 500 psi on the second.

(g) Pre-Heating:

This increases the efficiency of drum drying. It is carried out by heating the feed-concentrate to 74-85°C before pumping it into the reservoir between the drums.

(h) Drum drying.

(i) Packaging.

(j) Storage.

II. Skim Milk Powder:

Same as for whole milk powder except that ‘standardization’ and ‘homogenization’ are omitted, while ‘clarification’ is taken care of during centrifugal cream separation.

Method of Manufacture by Spray Process of Whole Milk Powder (WMP) and Skim Milk Powder (SMP):

Flow diagram = Combined for WMP and SMP (Adapted from Hall and Hedrick):

Details:

I. Whole Milk Powder:

(a) Receiving Milk:

Only high-grade milk should be accepted.

(b) Cooling:

To preserve the quality of milk.

(c) Standardization.

(d) Pre-Heating:

For efficient filtration/clarification

(e) Filtration Clarification:

The chief object of this is to remove extraneous matter. This operation can also be done before standardization.

(f) Homogenization:

Commonly done, if direct reconstitution of dry whole milk is contemplated. Without homogenization, the fat may churn during agitation while combining it with water. Another merit of homogenization is improvement in the keeping quality of the powder. A pressure of 3000 psi (2500 psi on the first stage and 500 psi on the second) at 63 to 74°C (145 to 165°F) is sufficient.

(g) Heat:

This actually serves the purpose of forewarming/pre- heating. The main object is to prolong the shelf life of the dried product by inactivation of lipase. This pre-heating should also ensure pasteurization, thus reducing the viable micro-organisms.

A beneficial influence on the heat-stability of the product may follow from the pre-heat treatment. Several optimum temperature-time combinations of heating in the range of 82°C (180°F) for 15 minutes to 93°C (200°F) for 3 minutes are used in commercial practice.

Note:

Low heat-treatment minimizes cooked flavour development in the product but does not develop anti-oxidants, which delay oxidation in whole milk powder and thereby help improve its keeping quality.

(h) Condensing:

Normally a concentration of 35 to 45 per cent total solids is produced, and the concentrate is continuously removed from the evaporator with the help of a continuous density tester.

(i) Pre-Heating:

The temperature of the condensed milk after leaving the evaporator is boosted to approximately 71°C (160°F) in a heat-exchanger before being pumped, in order to increase the efficiency of spray drying.

(j) Pumping:

This forces the hot concentrate through the atomizer. Generally a pressure of 2500 psi is used.

(k) Spray Drying:

The concentrated milk is dried with inlet air at 143 to 232°C (300 to 450°F) and exit air at 74 to 93°C (165 to 200°F), depending on product characteristics. To reduce heat- damage during drying and yet obtain the desired moisture, a low exhaust air temperature is preferred.

(l) Cooling:

The dry whole milk should be removed promptly from the hot air stream to maintain better flavour and body characteristics and also keeping quality. The higher the temperature and the longer the time the product is above the melting point of fat the greater the amount of free fat obtained, thus adversely effecting keeping quality. Hence, it is essential to cool the powder immediately to a temperature below the melting point of fat.

(m) Sifting:

A 12-mesh screen is used for sifting dry whole milk.

Note:

The size of (powder) particles is designated by microns or mesh. A micron (µM) is one-millionth part of a metre, i.e. 0.001 mm. Mesh refers to the number of screen openings per lineal inch. The opening also depends upon the size of the wire used in making the mesh material.

The Tyler sieve, the U.S. scale sieve and the B.S.S. sieve use different sizes of wire for making up the screen. A 100-mesh Tyler sieve has an opening of 0.147 mm., which is equivalent to 147 µM; the 400-mesh opening is equivalent to a 38 µM diameter. For smaller sizes, a microscopic analysis is made to determine the particle diameter.

(n) Packaging.

(o) Storage.

II. Skim Milk Powder:

(a) Receiving milk

(b) Cooling

(c) Pre-Heating and Separation:

Cream can be separated with or without pre-heating the milk; special cold milk separators are required for the low-temperature method. The most important consideration is a high degree of separation efficiency (not more than 0.1 per cent fat in skim milk).

(d) Pasteurization:

I. Low Heat Skim Milk Powder:

Its manufacture requires that heating be carefully controlled during pasteurization so as to produce the minimum number of heat-induced changes. Control of both temperature and time is important. Higher temperature and/ or longer holding time contribute directly to whey protein denaturation—which is measured by whey protein nitrogen (WPN) content per g. of powder. It should have a WPN of 6 mg. or more.

II. High Heat Skim Milk Powder:

A higher heat treatment imparts good baking qualities to the powder. For this purpose, besides pasteurizing at 71°C (161°F) for 15 seconds, the powder is pre-heated a second time at 85°C (185°F) for 20 minutes before being condensed. Its WPN content should be not more than 1.5 mg.

(e) Condensing:

Normally a concentration of 40 to 42 per cent total solids is obtained.

(f) Re-Heating:

This is done to increase the efficiency of drying.

(g) Filtration:

This is done to remove any extraneous matter from the concentrate before atomization, so that it can function smoothly.

(h) Pumping:

This is done to force the hot concentrate through the atomizer.

(i) Spray Drying:

Low heat skim milk powder is dried up to 3 to 4 per cent moisture, while high heat skim milk powder usually has not more than 3.5 per cent moisture.

(j) Cooling:

Most milk driers have a continuous removal system to immediately separate the dry product from the hot air stream. The dry product should be cooled at once. If the skim milk powder is too hot when packaged, it may become lumpy due to ‘heat-caking’, and development of storage defects in flavour and colour may be rapid.

(k) Sifting:

A 25-mesh screen is commonly used for sifting dry skim milk (see under whole milk powder).

(l) Packaging.

(m) Storage.