In this article we will discuss about the steps involved in the manufacture of milk. The steps are: 1. Receiving Milk 2. Pre-Heating 3. Filtration/Clarification 4. Cooling and Storage of Raw Milk 5. Standardization 6. Pasteurization 7. Homogenization 8. Bottling/Packaging 9. Storage.

Step # 1. Receiving Milk:

Milk may be delivered to the Milk Plant/ Dairy in cans or tankers (road or rail). The milk in these containers has to be graded, emptied, measured by weight or volume, sampled, and bulked to provide continuity of supply to the pasteurizing equipment.

In the absence of mechanical aids, the cans are off-loaded manually to the tipping point, where the lids/covers are removed and the milk inspected. They are then tipped manually and both cans and lids passed on to a can-washer via a drip saver or drain rack. Where a higher throughput is required, the procedure is mechanized and the cans are unloaded directly from the truck onto the conveyor (power-driven or by gravity-roller) and the tipping, sampling, and weight-recording may be completely automatic.

If milk is measured by weight, as is usual, it is tipped into the weigh tank/pan; this is suspended from a weighing machine, the indicating dial of which is calibrated in weight and so placed that it can be easily seen by the checker. Two weigh tanks can be used for quick reception.

The discharge valve has a large diameter so as to permit rapid emptying, and should be easily controlled by the tipper/checker. The milk is discharged into a dump tank placed immediately below the weigh pan; from this, milk may be pumped continuously to a raw-milk storage tank, normally situated at a higher level to give gravity flow to the pasteurizing plant.

The reception of milk from large rail or road tankers is primarily a matter of providing a covered area under which emptying and subsequent cleaning can take place. The tanker outlet must be connected to sanitary piping.

The milk may be removed by a milk-pump, situated at a lower level than the tanker, or a compressed-air line may be connected to the top of the tanker and the milk forced out by air pressure. Washing and sanitization of the tanker should follow immediately after emptying is complete. The measurement of milk delivered by tankers can be done either by using a weigh-bridge or flow-meter.

If milk is being received from milk-chilling centres, it has already been graded, weighed, sampled and cooled. It may be weighed and sampled again, or the Centre’s report may be used. The latter procedure applies especially to tanker deliveries.

Milk reception should be so planned and the equipment so chosen that intake operations are expedited. This is especially important where large volumes of milk are received. Delays permit deterioration of milk awaiting dumping, increase labour costs and may increase the operating cost of the can-washer. The deliveries of milk should follow a schedule.

If the milk is received continuously during the scheduled period, operations in the plant will not be interrupted and employees in the various sections will be fully occupied. The aim should be to complete milk reception within 3-4 hours, especially in tropical countries.

Market milk requires milk of a higher quality (from the standpoint of good health, flavour, sanitary quality, keeping quality and aesthetic quality) than is required by any other branch of the dairy industry. The quality of the incoming (intake) milk greatly influences the quality of the processed milks (or manufactured products).

It is well known that the sanitary quality of milk on the receiving platform/dock depends on its background on the farm, viz., healthy cows, clean milk production, clean utensils, freedom from colostrum, prompt cooling, and refrigerated transport. However, there is need for systematic and thorough inspection of all milk supplies every day by conscientious and experienced milk graders.

When milk is received at the Milk Plant/Dairy, it should be at 5°C or below. The milk should be clean, sweet, of pleasant flavour, free from off-flavours and reasonably free from extraneous material. Contamination with antibiotics, pesticides and other chemicals or metals is highly undesirable. No abnormal milk should be accepted. Acid development is objectionable, for not only does it indicate an excessive bacterial count, but it also reduces the heat-stability of milk.

Milk Reception Operations:

The operation of receiving milk may be subdivided into:

(a) Unloading;

(b) Grading;

(c) Sampling;

(d) Weighing; and

(e) Testing.

(a) Unloading:

The motor truck carrying the filled milk cans is backed up (or brought aside) to the unloading platform. The milk cans are then unloaded manually. If the level of the truck surface is in line with the platform, the unloading requires the least effort. (No lifting up or down, but only pulling on a level surface). Then the milk cans are assembled for grading in a definite order, according to each supplier, viz., the contractor or patron. If a milk tanker is being used, it is first properly positioned so that connections can be made conveniently.

(b) Grading:

This refers to the classification of milk on the basis of quality, for price-fixing purposes. It is well known that the quality of the finished product depends on that of the raw material used. The milk grader is the key man for the proper selection of milk. The principle of grading is based on organoleptic (sensory) tests, such as those for smell (odour), taste, appearance and touch; acidity; sediment, etc. These are included under platform tests.

Note:

The term ‘Platform Tests’ includes all those tests which are performed to check the quality of the incoming milk on the receiving platform, so as to make a quick decision regarding its acceptance/rejection. They are performed on each can/tanker of milk with the object of detecting milk of inferior or doubtful quality, so as to prevent it being mixed with high-grade milk. Sometimes the term ‘Rapid Platform Test’ is used to refer mainly to the organoleptic or sensory tests which take very little lime to perform.

The technique of grading milk may be described as under:

(i) Milk Tanker (Road/Rail):

Actually the grading should have been done at the milk collection-cum-chilling centre. As the milk should be cold (5°C or below), it is not possible to detect off- odours. Only the appearance can be noted, as testing of raw milk is usually avoided. After thoroughly mixing it for 5-10 minutes, a sample is taken for laboratory testing.

(ii) Milk Can:

The main tests applied to each can of milk consist of smell, appearance and temperature (touch); other tests such as taste (seldom carried out with raw milk) and sediment might be used to substantiate the initial findings. Tests involving time, laboratory facilities and special techniques are best done by the quality control technician, for which a sufficiently large sample is properly taken as the milk is being received. (Even if the cans of milk have been despatched from a chilling centre, it is wise to inspect each can separately.)

(c) Sampling:

The importance of securing an accurate and representative sample of milk for subsequent chemical and bacteriological analysis cannot be over-emphasized. While strict precautions regarding sterility of the stirrer, sampler, container, etc., are required for obtaining a bacteriological sample, dryness and cleanliness of the above equipment should suffice for a chemical sample.

The first prerequisite of sampling is thorough mixing of the milk. This can be done with a plunger or stirrer (agitator), operated manually or mechanically in the milk-in-cans or tankers, as the case may be. With the former, a representative sample may also be taken after quick dumping of the milk into the weigh tank, whereby it gets mixed so thoroughly that a representative sample may be taken without further mixing.

Samples may be individual; composite (mixture of two or more individual lots of milk); drip (representing the entire day’s supply); etc. Samplers may be: dipper; tube or proportionate (also known as milk thief); automatic vacuum; drip; etc.

If the composite sample is to be successful, the milk must be kept sweet while the sample is being assembled. This is accomplished by use of a preservative. It is a good plan to place the preservative in the empty bottle before milk is added. A wide- mouthed glass bottle with a rubber stopper has been found to be the most reliable and practical container for keeping composite samples of milk or cream.

The common preservatives used are:

(i) Mercuric Chloride or Corrosive Sublimate:

This is very poisonous. It may be added in the form of tablets, which are coloured (usually bright red) to prevent the milk being mistaken for food.

(ii) Formalin:

This is a 40 per cent solution of formaldehyde. Being in liquid form, it is very convenient to handle. However, it interferes with the fat test.

(iii) Potassium Dichromate:

This is not as effective as the above two, but it is easy to handle in dairy plants because it is available in tablet form.

Note:

The composite samples should be stored in a cool place away from direct sunlight. Each bottle should be properly labelled.

(d) Weighing:

This is an essential step in accounting for milk receipts and disposal, making payments for milk, etc. The milk- in cans is dumped into the weigh tank, either manually or mechanically. The tank is mounted on scales and the scale dial set at zero when the empty tank is on the scale, thus enabling the operator to-make a direct reading of the weight of the milk. Automatic printing of the weight is also now becoming common. (Weighing is facilitated by the use of a dial reading or some other indicating scale, rather than a beam scale.)

The milk in tankers (road or rail) may be measured by volume by passing it through a flow-meter; and its measurement converted into weight by multiplying the volume with an agreed density. In case of road milk tankers, another common alternative is to use a weigh-bridge, the tanker being weighed once when it is full, and again after it has been emptied.

However, any mud or snow on the tanker should be washed off before weighing, adjustments to fuel or water should not be made between weighings, and the driver and his accoutrements should be either on or off the vehicle on both occasions.

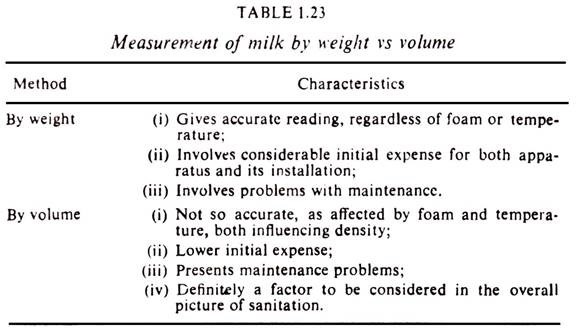

The characteristics of measuring by weight and by volume have been shown in Table 1.23.

(e) Testing:

Apart from initially accepted/rejected lots of milk, there are always some of doubtful quality. All the accepted lots have already been properly sampled; these, together with samples of the remaining two categories, have to be tested in the quality control laboratory for the final verdict of acceptance/rejection.

Further, a record of the chemical and bacteriological quality of all accepted milk has to be maintained for making payments, etc. (For ‘Methods of Test’, consult Indian Standards: IS: 1479 (Part I), I960; (Part II), 1961; (Part III), 1962.)

The common quality control tests have been given in Table 1.24.

Step # 2. Pre-Heating:

This term refers to heating before the operation which follows immediately. The milk is pre-heated for efficient filtration/clarification. Pre-heating becomes essential if the incoming milk is cold, as otherwise the flow of milk is hampered. As the temperature of the milk increases, the viscosity decreases and more efficient filtration/clarification results. The usual temperature of pre-heating is 35-40°C. and the equipment used may be a plate or tubular heater.

Step # 3. Filtration/Clarification:

To improve the aesthetic quality of milk by removing visible foreign matter which is unsightly and may therefore cause consumer complaints.

Principle:

While filtration removes suspended, foreign particles by the straining process, clarification removes the same by centrifugal sedimentation.

Types of Filters and Clarifiers:

There are two types of filters/clarifiers, viz., those that operate with cold milk and those operating with warm milk. While the latter is commonly used throughout the world, the former has the following advantages and disadvantage-

Advantages:

(i) No need for pre-heating, and

(ii) Less likelihood of ‘soluble’ dirt going into the solution.

Disadvantage:

The flow of milk is slow.

General Construction and Operation of Filters and Clarifiers:

Filters:

Their important features are:

(i) A filter cloth or pad of the desired pore size which can retain the smallest particle;

(ii) A frame or support to compress and hold the margins of the cloth or pad, so that milk can pass only through the pores;

(iii) A perforated metal or other support for the cloth or pad which will not tear or break under the pressure of the milk;

(iv) An enclosure to confine both the unfiltered and filtered milks in a closed system fitted suitably with inlet and outlet connections for sanitary piping;

(v) A means of distributing the incoming stream of milk so that it does not damage or tear any part of the cloth or pad by vigorous washing, and

(vi) A design so planned that filter cloths or pads can be changed quickly, and all parts are easily accessible for washing.

Where continuous operation is essential, or where large volumes of milk are processed, two or more filters are used so that operations need not be interrupted when it becomes necessary to change the filter cloth. The frequency with which the cloth is changed will depend upon the temperature of the milk, the amount of foreign matter in it, etc. It is best to use filter cloths only once; a washed cloth, besides being a source of contamination, results in inefficient filtration.

Clarifiers:

In general appearance and construction, clarifiers are quite similar to centrifugal cream separators.

However, the main differences are:

(i) In clarifiers, there is only one outlet, while in separators there are two (one for cream and another for skim milk);

(ii) The discs in the clarifier bowl are smaller in diameter (so as to provide a large space for the accumulation of slime) than separators, and

(iii) The milk distribution holes are at the outer edge of the discs in clarifiers, but near the centre in separators.

Location of Filter/Clarifier in the Processing Line:

In some cases, it is the practice to locate the filter in the raw milk line before the milk enters the pasteurizing plant; in others, the filter is located at a convenient point in the regeneration section where the temperature of the milk may be 50-60°C.

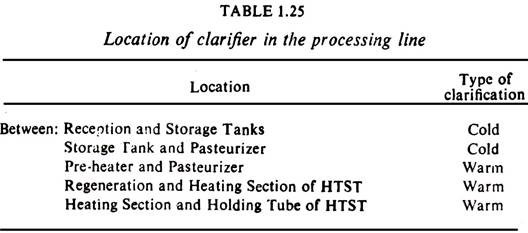

The clarifier may be located in one of the following places in the processing line, as shown in Table 1.25:

Relative Efficiency:

Clarification removes sediment much more efficiently than filtration; clarifiers remove still finer particles that escape filters.

Composition of Clarifier Slime:

While the material retained on the filter cloth includes suspended foreign particles, milk fat, protein and some leucocytes and bacteria, the slime that accumulates in the clarifier bowl consists of foreign matter, milk proteins, leucocytes, fragments of the secreting cells from the udder, fat, calcium phosphate and other ash, bacteria and occasionally red blood corpuscles.

The amount of clarifier slime is influenced by the amount of foreign matter, the condition of the udder, the stage of lactation, the bacterial count and acidity of milk, the clarifying temperature, the velocity of the bowl, and the amount of milk run through the bowl (or the length of time the bowl is run).

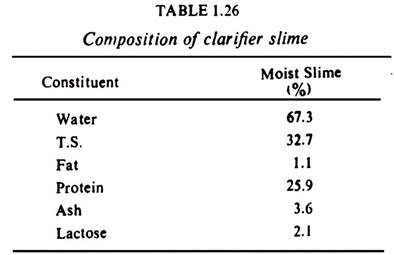

The composition of clarifier slime varies considerably due to the factors stated above. Separator slime is usually considered to be identical with clarifier slime. The typical composition of clarifier/separator slime under American conditions is given in Table 1.26.

General Remarks:

(i) Both filtration and clarification tend to decrease the depth of the cream layer that will form on milk, and this effect becomes more pronounced as the processing temperature increases.

(ii) Neither filtration nor clarification improve the keeping quality of milk.

(iii) Milk should neither be filtered nor clarified after pasteurization, as this might contaminate it.

Note:

Bactofugation is the process of removing 99 per cent of the bacteria in milk by centrifugal force. It is claimed that this method triples the shelf-life of market milk. Generally it removes the bacteria from milk with two centrifugal clarifiers in a series, the first operating at high velocity (20,000 rpm). The process is considered supplementary to pasteurization, for it is still necessary to destroy the bacteria not removed.

Step # 4. Cooling and Storage of Raw Milk:

Cooling (in the Dairy):

As soon as milk is received in the Plant, it is chilled to 5°C or below and stored cool till used, to prevent deterioration in its bacteriological quality during the interim period.

Methods (in the Dairy):

i. Surface Cooler:

Either an Individual Unit or Cabinet type. The latter consists of two or more individual units, compactly assembled, and enclosed in a cabinet. It is usually larger than those used on the farm/chilling centre.

ii. Plate Cooler:

For continuous cooling. Commonly used in the dairy industry, especially for large-scale handling. It consists of a number of thin, flat, grooved, stainless steel plates, sealed at the edges with a gasket and clamped tightly within a press.

The spaces between the plates are occupied alternately by the milk and the cooling medium (chill water/brine); thus one side of each plate is exposed to milk and the other side to the cooling medium. Plates may be added to provide increased capacity at nominal cost.

Advantages:

(i) Cooling (heat-exchange) is quick and efficient;

(ii) Not exposed to air-borne contamination;

(iii) No evaporation losses;

(iv) Cleaning and sanitization are easy.

iii. Internal Tubular Cooler:

For continuous cooling. It consists of a stainless steel tube about 2.5 to 5.0 cm. in diameter surrounded by a similar tube, forming a concentric cylinder. Several such tubes may then be connected in a series to obtain sufficient cooling. The cooling medium flows counter to the milk flow.

Advantages:

(i) Cooling is quite efficient;

(ii) Not exposed to air-borne contamination;

(iii) No evaporation losses.

Disadvantages:

(i) Cooling efficiency is lower than plate cooler;

(ii) Larger floor space is needed.

iv. Jacketed Vat/Tank:

For batch cooling, especially of small quantities. It consists of a tank within a tank, with the space between the two being used for circulation of the cooling medium, by either pump or main pressure. An agitator is provided to move the milk (which is in the upper tank) for rapid cooling.

Disadvantages:

(i) Cooling efficiency is rather low;

(ii) Too much agitation is required, which causes churning and impairs the creaming property of milk.

Storage:

Modern milk plants hold both raw and pasteurized milks for a much longer period than before. Normally the milk storage capacity is equal to one day’s intake. This allows a more nearly uniform work-day for processing and bottling operations with less dependence on the time for receiving raw milk.

Storage tanks are used in Milk Plants for the storage of raw, pasteurized, or processed products, often in very large volumes. Because of the longer periods of holding, storage tanks are among the most important items of equipment.

They must be designed for ease in sanitization, preferably by the circulation-cleaning method. In addition, the tanks should be insulated or refrigerated, so that they can maintain the required temperature throughout the holding period. Agitation should be adequate for homogeneous mixing, but gentle enough to prevent churning and incorporation of air.

Objects:

(i) To maintain milk at a low temperature so as to prevent any deterioration in quality prior to processing/product manufacture;

(ii) To facilitate bulking of the raw milk supply, which will ensure uniform composition;

(iii) To allow for uninterrupted operation during processing and bottling;

(iv) To facilitate standardization of the milk.

Types:

(i) Insulated or Refrigerated:

In the former, there are 5 to 7.5 cm. of insulating material between the inner and outer linings; in the latter, the space between the two linings is used for circulation of the cooling medium. Another variation of the refrigerated type is the cold-wall tank.

(ii) Horizontal or Vertical:

While the former requires more floor space and less head space, the latter requires less floor space and more head space. Modern circulation cleaning methods have made very large vertical storage tanks practical.

(iii) Rectangular, Cylindrical or Oval:

Of these, the first suffers from the disadvantage of having dead corners during agitation, while the other two do not.

(iv) Built for Gravity Flow, Air-Pressure or Vacuum Operation:

The first is the most common. However, air pressure is sometimes used to evacuate the product. This requires special construction of the storage tank for greater strength than necessary for normal operations under gravity flow (i.e., atmospheric pressure).

Location:

In one system, the storage tanks are located on an upper floor. The milk is pumped from the receiving room to the floor above. It then flows by gravity to the pre-heater, filter or clarifier, pasteurizer, cooler and bottling machine. In another system, the milk is pumped from the storage tanks through a pre- heater and filter into the pasteurizer. Thence it may flow by gravity to the cooler, or it may be pumped to the cooler while hot.

Parts of a Storage Tank:

(i) Sight glass;

(ii) Light glass and lamp;

(iii) Ladder;

(iv) Manhole;

(v) Agitator;

(vi) Outlet valve;

(vii) Inlet;

(viii) Air vent;

(ix) Safety valve;

(x) Legs;

(xi) Indicating thermometer;

(xii) Volume-meter.

Step # 5. Standardization:

Standardization of milk refers to the adjustment, i.e., raising or lowering, of the fat and/or solids-not-fat percentages of milk to a desired value, so as to conform to the legal or other requirements prescribed.

Procedure:

Milk is standardized by the addition of milk or cream with a higher or lower fat percentage than that of the material to be standardized; sometimes the addition of skim milk will do to solve the problem, it is necessary to find the relative amounts of the original material and the standardizing material to be mixed together to give a product with the desired fat content.

Once these relative amounts/proportions have been determined, it is easy to calculate the exact amount of each which must be mixed together to give a certain weight of the finished product or the exact amount of standardizing material needed to use up a given weight of milk or cream. A simple scheme, the Pearson’s Square, can be used to calculate the relative quantities of the materials involved in a standardization problem. It should be remembered that all measurements based on these calculations are by weight and not by volume.

The Pearson’s Square method is as follows- draw a square and place in the centre of it the fat percentage desired. Place at the left-hand corners of the square the fat percentage of the materials to be mixed. Next, subtract the number in the centre from the larger number at the left-hand side of the square and place the remainder at the diagonally opposite right-hand corner.

Subtract the smaller number on the left-hand side from the number in the centre and place the remainder at the diagonally opposite right-hand corner. The numbers on the right-hand side now represent the number of parts of each of the original materials that must be blended to make a product with a fat test given by the number in the middle of the square.

The number at the upper right corner refers to the parts of material whose fat test was placed at the upper left corner, and the number at the lower right corner refers to the parts of material whose fat test was placed at the lower left corner. If the numbers on the right are added, the sum obtained will represent the parts of the finished product, with the fat test given by the number obtained in the middle of the square.

Step # 6. Pasteurization:

The term pasteurization has been coined after the name of Louis Pasteur of France, who in 1860-4 demonstrated that heating wine at a temperature between 122 to 140°F (50 to 60°C) killed the spoilage organisms and helped in its preservation.

The application of this process gave rise to the new term ‘Pasteurization’, which soon became current in technical language. Although Louis Pasteur pioneered studies on heat-treatment for preservation, pasteurization of milk was first attributed to Dr. Soxhlet of Germany in 1886.

Step # 7. Homogenization:

A considerable proportion of market milk pasteurized in developed dairying countries is now homogenized as well. The homogenizer may be located immediately after regenerative heating, or between final heating and holding, or after FDV and before regenerative cooling.

Step # 8. Bottling/Packaging:

The pasteurized and cooled milk is promptly bottled/packaged so as to serve the dual purpose of:

(a) Protecting the milk against contamination, loss, damage or degradation (due to: micro-organisms or insects; exposure to heat, light, moisture or oxygen; spillage, evaporation or pilferage), and

(b) Helping in the sale and distribution of the milk (by packaging it in an easy-to-carry-and-open, sufficiently strong and leak-proof, non- tainting container).

Bottling and Capping:

Bottles:

The glass bottle is still universally used. It is usually transparent, although in some countries brown bottles have been tried. (Brown bottles prevent light-induced off-flavours in milk; but on the other hand, the product is not visible for inspection.) The glass bottle is generally round, but may also be square in shape (as in the USA); the latter is considered to be more economical of storage space. Light-weight yet sturdy, the glass bottle is best since it decreases the pay-load of retail vehicles.

Bottles should be examined for their colour, capacity and strength, before use.

The tests include the following:

(i) Colour and appearance;

(ii) Shape;

(iii) Dimensions (height and neck diameter);

(iv) Weight;

(v) Serrations;

(vi) Minimum wall thickness;

(vii) Nominal capacity;

(viii) Strength or durability (these consist of thermal shock test, internal pressure test, impact test, polariscope examination, etc.).

In plants of small capacity, milk may be bottled with hand fillers operated manually with a lever and capable of filling 4 to 12 bottles at a time. The caps are then usually applied with a hand capper. In larger plants, automatic, continuous, mechanical bottle fillers and cappers are used. These are broadly of two types, viz., gravity fillers and vacuum fillers.

In the former, the milk flows by gravity into the bottles as they are pressed against the filling valves; in the latter, the bottles are filled by creating a vacuum within them. The milk from the cooler usually goes directly into the bowl of the bottle-filling machine, the connecting pipe being equipped with a valve that regulates the flow. Bottle washing operations are so timed in relation to the processing of milk that washed and sanitized bottles arrive at the filler as needed for immediate bottling.

There are two principles in filling, viz. level filling and quantity filling. Level filling is quicker and more common; most bottle fillers are designed to fill milk bottles to a pre-determined level; however, a constant low temperature of milk at the time of filling should be maintained. Quantity filling, although more accurate since it is not affected by either temperature or foam, is slower and hence seldom used.

Bottling (Bottle Filling):

(a) Gravity Fillers:

These consist mainly of six different parts, viz., the drive, bowl, filler valves, carrier, capper and star wheels. The circular bowl receives the milk to be bottled. The level of milk is kept constant by a float valve on the inlet pipe. Filling valves are attached radially to the bottom of the bowl. Bottles are fed by hand or directly from the bottle washer by a conveyor.

They are mechanically centred into lifters which are located directly under the filling valves and which revolve with them. These lifters rise automatically as the filler revolves and the mouth of the bottle is forced against a tightly fitting rubber valve.

The rising bottle pushes up the valve and the milk flows down into the bottle. As the filling valve almost completes a revolution, the lifter on which the bottle is carried is lowered automatically and the valve closes and remains closed until the next bottle opens it. The filled bottle is then transferred to a capper where it is automatically sealed and the lifter, now in the lowered position, is ready to receive another empty bottle for filling.

While the bottle is being filled, the air which is displaced by the incoming milk escapes through a vent tube, which extends from the bottom of the valve sleeve to a point above the milk level in the bowl. The height of the bowl- tank is adjusted by the operator to suit the size of each bottle that is to be filled.

Bottles are automatically discharged from the capper onto a conveyor that delivers them to an accumulating table, from where they may be loaded into crates manually or mechanically.

Advantages:

(i) Relatively simple to operate;

(ii) Maintenance not too complicated;

(iii) Easily and swiftly cleaned.

Disadvantages:

(i) Slow filling and hence limited capacity;

(ii) Leakage losses high (due to badly sealed bottle, bottle with chipped mouth, faulty valve, etc.).

(b) Vacuum Fillers:

These may be either vacuum-assisted (single-bowl) or straightforward vacuum (double-bowl) types. In the former, the typical gravity bowl, which has open vent tubes and conventional gravity valves, is closed with an air-tight cover. In the latter, there is a rotary bowl and a float bowl.

The float bowl is slightly below the level of the tops of the filling head. When the bottle is raised against the rubber ring on the filling head, a seal is formed and air inside the bottle is immediately drawn out through vertical vacuum pipes, and the milk is drawn from the float bowl through the milk pipes to the filling head and is released into the bottle.

Foam is drawn off through the vacuum pipes into the vacuum tanks. Excess milk collecting in the vacuum tank automatically goes into the float bowl. Towards the end of the revolution of the filler, the lifters, on which the bottles are carried, are lowered, and the seal is broken. Any milk remaining in the milk pipe syphons back into the float bowl and that remaining in the vacuum line is drawn back into the vacuum tank.

Advantages:

(i) Rapid filling;

(ii) Will not fill a bottle with a chipped mouth or bad seal, thus saving milk;

(iii) No milk drip through faulty valves.

Disadvantages:

(i) Maintenance complicated;

(ii) Relatively complicated to operate;

(iii) Cleaning more time-consuming.

Caps and Capping:

The capping machine is often incorporated into the filler, and in any case, its work must synchronize with it.

The milk bottle cap or closure has three main functions:

(i) To retain the milk within the bottle;

(ii) To protect the pouring lip from contamination; and

(iii) To seal the bottle against tampering. (In this case, tampering refers to the removal or replacement of milk from a bottle without this being evident from the appearance of either the bottle or the milk within it.)

The caps may be:

(i) Cardboard discs, impregnated with a moisture-proof layer (paraffin wax or polythene);

(ii) Aluminium foil caps;

(iii) Crown corks.

The cardboard discs with separate hoods were the first to be introduced, but are not much used now. The aluminium foil cap is most commonly used. It is either pre-formed or formed-in-place, both types having their advantages and disadvantages. The foil may be 0.05 to 0.15 mm. thick and of 50 mm. width.

Crown corks are generally used for sterilized milk; they are made of lacquered tin plate, the inner surface of which is lined with water-proof paper/polythene, and are more expensive. (All types of caps or closures can be printed or embossed with names or trade-marks and can be coloured for coding purposes.)

Inspection of Filled Bottles:

Before being (manually) placed in crates, filled milk bottles should be inspected for dirt, etc. by rotating them as they are removed from the machine.

Decrating and Recrating of Bottles:

Removing dirty bottles from crates (decrating) and refilling them with bottles of pasteurized milk (recrating) are among the most back-breaking and labour- consuming operations in the dairy. Both decrating and recrating machines look the same. The decrator lifts the empty bottles by vacuum-operated rubber-grippers and rejects any that are damaged.

The recrator lifts the filled bottles by compressed-air operated rubber-grippers. In decrating, the crates of empty bottles are at first correctly positioned before lifting, while in recrating, a special marshalling mechanism allows bottles from the filler to assemble in correctly positioned groups, ready to be picked up for transfer to the crates.

Crate Stacker:

This stacks crates containing filled bottles, thereby relieving labour of another back-breaking job.

Packaging:

Although the glass milk bottle is still the traditional packaging medium for retail milk distribution, single-service paper/plastic containers are increasingly being adopted for the same purpose. A survey has shown that in some European countries they have captured two-thirds of the market.

A beginning in this field has also lately been made in India. As far as milk packaging is concerned, paper is a carrier for a water-proof layer of either polyethylene or wax. The provision for 5 to 10 per cent of synthetic fibres is said not to influence the printing or folding capacity of paper, but rather to provide better wet strength.

Dominated, in milk packaging, by polyolefines (such as polypropylene and poly- ethylenes), used singly or blended to offer a wide range of materials, plastics have superseded paper in recent times. The polyolefines of interest are coating grades for cartons, film grades for sachets and extrusion/blowing grades for bottles.

Cartons are commonly used for both bulk and retail sale. They are made of combinations of food grade paper and wax or plastics. The distribution advantages of cartons are- maximum space utilization in vehicles and storage, ability to carry attractive printing, and convenience for the purpose of stacking milk on super-market shelves.

The carton systems in common use are- Perga (U.K.); Pure Pak (U.S.A.); Zupack, Blockpack (W. Germany); and Tetra Pak (Sweden). When filling the cartons, either preformed or pre-cut blanks may be used. Pre-formed cartons are supplied in a fully erect form ready for filling; in the pre-cut system the blanks are supplied in a knocked down shape and the final carton is set up, formed, filled and sealed on one machine.

Sachets are flexible water-proof bags. Since it is difficult to pour from sachets, they are usually equipped with a jug. The sachet systems in common use are- Polypack, Bertopack (Switzerland); Finnpack (Finland); Milk-Pack, Rotapack (W. Germany); and Prepac (France). Sachet filling of milk usually follows a form/fill/seal system.

The sachets are formed from a reeled film over a shoulder and tube-forming sealer. Their size is changed simply by pushing a button without stopping the machine. They are filled by a time-regulated valve accurate within +3 ml. /litre. Ultra-violet light is used to sterilize the inside of the film.

Glass Bottle vs. Paper/Film Package:

The relative advantages and disadvantages of paper/film packaging of milk over bottling are given below:

Advantages:

(i) Light in weight, easy to handle and no danger of breakage;

(ii) Distribution costs lower (occupies less space, lower pay-load due to light weight, no collection of empties);

(iii) Bottle-washing costs eliminated (saving in equipment, detergents, steam, etc.);

(iv) Tamper-proof;

(v) Effective sales message can be printed;

(vi) Less noisy (during filling, sealing and transportation);

(vii) No exposure to sunlight;

(viii) Filling machinery compact and occupies much less space;

(ix) No container deposit needed.

Disadvantages:

(i) Costs higher per unit milk distributed;

(ii) Product not visible;

(iii) Difficult to remove cream;

(iv) Inspection of milk (for sediment) not possible;

(v) Regular supply of special paper/film essential;

(vi) Not so easy to open; and

(vii) Some cases of leakage may occur.

Step # 9. Storage:

In any milk plant, it is necessary to provide refrigerated rooms where milk can be stored until delivery. The temperature of milk storage rooms should be 5°C or below so as to check bacterial growth.

Distribution:

Distribution of milk is the last or final stage of the market milk industry. Others are preparatory to placing the product into the hands of the consumer. The quality of the product alone will not assure its wide distribution, which should be planned and executed intelligently.

Distribution facilities consist of:

(i) The physical equipment and personnel required for transporting the products from the milk storage rooms to the consumer/retailer;

(ii) Sales promotion personnel; and

(iii) Advertising.

A successful distribution programme requires:

(i) A product of high quality;

(ii) An attractive package;

(iii) Neat and courteous route salesmen;

(iv) Delivery equipment of pleasing appearance;

(v) Efficient use of men and equipment;

(vi) Effective advertising.

Route Organization:

This varies with the size and the type of business. In a small plant, the same drivers and trucks may deliver both wholesale and retail goods. In larger organizations, wholesale and retail distribution are usually handled by separate personnel and equipment. Wholesale routes handle larger volumes and have fewer stops than do retail routes. For economical operation, the truck should be utilized for a maximum number of hours per day for milk distribution.

Payment of Route Salesmen:

Three different methods are in use:

(i) Flat Salary:

Gives no incentive to sell more products, secure new customers, etc.;

(ii) Salary Plus Commission:

Most satisfactory;

(iii) Straight Commission:

Used when the driver owns the route and equipment.

Checking Out the Routes:

Different systems may be used for loading the trucks in checking out the routes. The trucks must be loaded rapidly so that the drivers are not delayed at loading stations.

The principal systems are:

(i) Loading directly from the storage rooms through one or more doors;

(ii) Using a long loading platform with conveyors from the milk-storage rooms;

(iii) Loading platform-trolleys in the storage room with orders for the different routes.

The platform trolleys are then wheeled onto the loading platform and finally loaded into the delivery trucks. (The first two systems are suitable for medium size and large plants, the third for small ones.)

Checking in the Routes:

This consists of verifying the driver’s count of empty bottles and unsold goods and conveying the bottles to the washers or to storage. The driver usually places the bottles on the platform, conveyor or platform-trolley.

Sales Outlets:

These include (for both wholesale and retail sales) the following:

(i) Home delivery;

(ii) Milk booths or distribution depots/bars;

(iii) Stores;

(iv) Soda fountains;

(v) Coin vending machines;

(vi) Automatic dispensers;

(vii) Factories, hospitals, jails, restaurants, schools, etc.;

(viii) Lunch counters.

Anticipating Daily Demand:

This is usually based on past experience, taking into consideration holidays, fairs and festivals, special events, etc.

Frequency of Distribution:

Due to highly changeable temperatures during most seasons and the lack of refrigeration facilities at the average customer’s home in India the milk has to be distributed twice daily, viz., morning and evening. In cold countries, one-time delivery is usual.

Utilization of Returned Milk:

Unsold milk presents a problem of economic disposal. Under tropical conditions, as in India, the returned milk should not be sent again for sale as liquid milk since exposure to high temperatures during its inward and outward journeys subject it to quality deterioration and hence may cause consumer complaints. The unsold milk can be given for separation or utilized for preparation of dahi, etc.

Systems of Collection for the Payment of Milk:

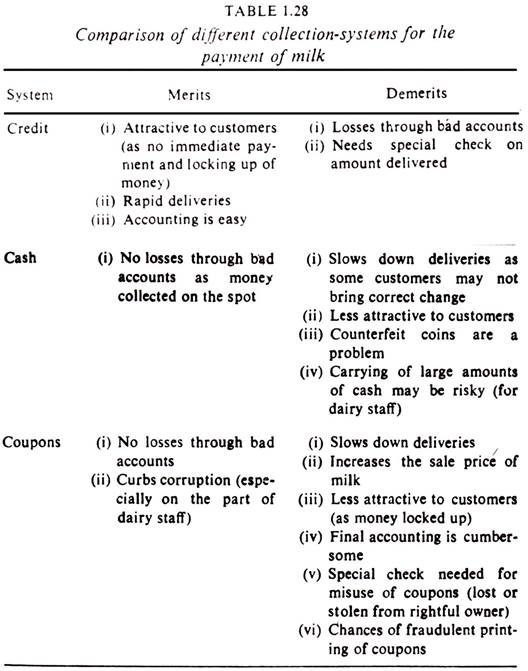

These are credit, cash or advance payment (coupon/monthly card). Their relative merits and demerits are given in Table 1.28.